Matsato Knife: Understanding Modern Kitchen Knife Design, Materials

Kitchen knives are among the most essential tools in food preparation. Whether used in home kitchens or professional culinary environments, knives play a central role in slicing, chopping, trimming, and preparing ingredients. The Matsato Knife is one example of a modern kitchen knife that reflects current trends in blade design, ergonomics, and material engineering. Understanding how knives like Matsato are designed and how they function can help users make informed decisions about knife selection, maintenance, and safe use.

This article provides a non-promotional, educational overview of kitchen knife design, focusing on blade construction, materials, ergonomics, maintenance, and performance characteristics relevant to knives such as Matsato.

The Importance of Kitchen Knives in Food Preparation

Kitchen knives serve as precision tools designed to perform specific cutting tasks efficiently and safely. A well-designed knife allows for controlled, accurate cutting while reducing strain on the user’s hand and wrist.

Common kitchen tasks include:

-

Slicing vegetables

-

Trimming meat

-

Chopping herbs

-

Cutting fruit

-

Preparing fish

Each task requires a blade capable of maintaining sharpness, structural integrity, and balance.

A knife’s design influences both its effectiveness and safety.

Blade Geometry and Cutting Efficiency

Blade geometry refers to the shape, thickness, and angle of the knife’s cutting edge. These factors determine how easily the blade moves through food.

Key aspects of blade geometry include:

Edge Angle

Most kitchen knives have edge angles between 15 and 20 degrees per side. Smaller angles produce sharper edges but may require more frequent maintenance.

Blade Thickness

Thinner blades reduce resistance when cutting soft ingredients, while thicker blades provide durability for tougher materials.

Blade Profile

The profile refers to the curvature of the blade. Curved blades allow rocking motions, while straighter blades support push cutting.

These design elements affect cutting precision and efficiency.

Steel Types Used in Kitchen Knives

The performance of a kitchen knife depends heavily on the type of steel used in the blade.

Common categories include:

Stainless Steel

Stainless steel contains chromium, which improves corrosion resistance. This makes it suitable for environments where moisture is present.

Advantages include:

-

Rust resistance

-

Lower maintenance

-

Durability

High-Carbon Steel

High-carbon steel is known for its ability to maintain sharp edges.

Characteristics include:

-

Strong edge retention

-

Easier sharpening

-

Higher hardness

However, it may require more maintenance to prevent corrosion.

Hybrid Steel Alloys

Many modern knives use hybrid alloys that combine corrosion resistance with hardness.

These materials balance durability and sharpness.

Blade Hardness and Edge Retention

Blade hardness is measured using the Rockwell Hardness Scale (HRC).

Higher hardness generally provides:

-

Longer edge retention

-

Sharper cutting performance

However, harder blades may be more brittle.

Lower hardness provides:

-

Greater flexibility

-

Improved resistance to chipping

Knife manufacturers select hardness levels based on intended use.

Knife Balance and User Control

Balance refers to how weight is distributed between the blade and handle.

A well-balanced knife provides:

-

Greater control

-

Reduced fatigue

-

Improved precision

Balance points often occur near the junction between blade and handle.

Proper balance improves overall handling.

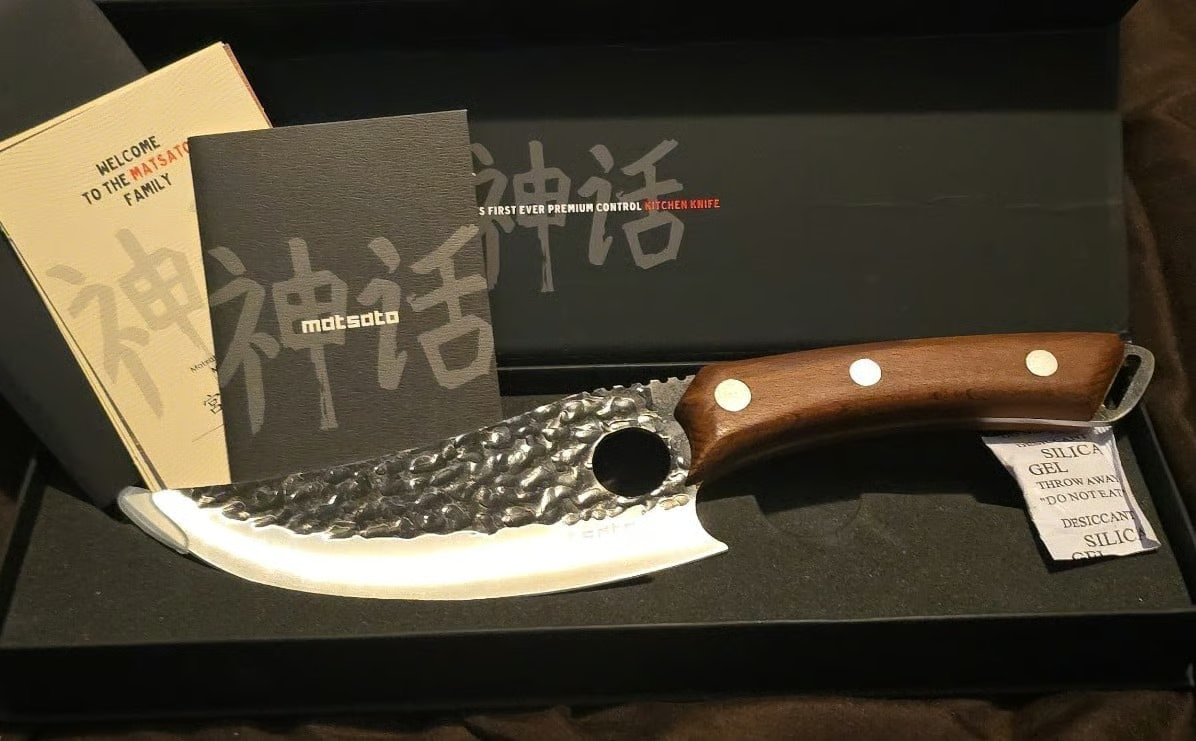

Handle Design and Ergonomics

Ergonomics refers to how a knife fits in the user’s hand.

Handle design affects:

-

Grip stability

-

Comfort

-

Control

Common handle materials include:

-

Wood

-

Polymer

-

Composite materials

-

Resin

Ergonomic handles reduce strain during extended use.

Handle texture also affects grip security.

The Role of Knife Weight

Knife weight influences cutting efficiency and user comfort.

Heavier knives may provide:

-

Greater cutting force

-

Stability during tough cuts

Lighter knives offer:

-

Faster movement

-

Reduced fatigue

Weight preferences vary among users.

Manufacturing Processes

Kitchen knives are manufactured using various methods.

Forging

Forged knives are shaped by heating and compressing metal.

This process may improve:

-

Structural strength

-

Grain alignment

Stamping

Stamped knives are cut from steel sheets.

This process allows:

-

Consistent blade shapes

-

Lower production costs

Both methods produce functional knives.

Sharpness and Cutting Performance

Sharpness refers to how fine the blade edge is.

Sharp knives:

-

Require less force

-

Improve cutting accuracy

-

Reduce crushing of ingredients

Sharp blades also improve safety, as less force is needed.

Dull knives may slip during use.

Knife Maintenance and Care

Proper maintenance helps preserve knife performance.

Key maintenance practices include:

Cleaning

Knives should be cleaned after use.

Moisture may affect metal surfaces.

Drying

Drying helps reduce corrosion risk.

Storage

Proper storage protects the blade edge.

Storage options include:

-

Knife blocks

-

Magnetic strips

-

Protective sheaths

Proper storage prevents damage.

Sharpening and Edge Maintenance

Knife edges gradually wear down through use.

Sharpening restores edge sharpness.

Methods include:

-

Whetstones

-

Honing rods

-

Professional sharpening services

Regular maintenance improves cutting performance.

Honing realigns edges.

Sharpening removes material to create new edges.

Cutting Techniques and Safety

Proper technique improves safety and efficiency.

Key safety principles include:

-

Using stable cutting surfaces

-

Maintaining controlled hand positions

-

Avoiding excessive force

Knife handling requires attention and care.

Proper technique reduces injury risk.

Applications in Home and Professional Kitchens

Kitchen knives serve both home cooks and professionals.

Home kitchens require versatility.

Professional kitchens require consistency and durability.

Knife design influences suitability for different environments.

Proper knife selection depends on intended use.

Material Science and Modern Knife Design

Advances in material science have influenced knife manufacturing.

Modern techniques improve:

-

Steel composition

-

Blade durability

-

Corrosion resistance

These improvements enhance performance.

Material engineering continues to evolve.

Environmental Factors and Knife Longevity

Environmental conditions influence knife lifespan.

Factors include:

-

Moisture exposure

-

Cleaning methods

-

Storage conditions

Proper care supports long-term durability.

Cultural Influence on Knife Design

Knife design varies across cultures.

Examples include:

-

Western chef knives

-

Japanese santoku knives

-

Cleavers

Each design reflects culinary traditions.

Different shapes support different cutting techniques.

The Role of Precision in Food Preparation

Precision improves food consistency.

Consistent cutting supports:

-

Even cooking

-

Improved presentation

-

Efficient preparation

Knife design influences precision.

Sharp, balanced knives improve cutting control.

User Skill and Knife Performance

Knife performance depends on both design and user skill.

Experienced users develop efficient cutting techniques.

Practice improves control and safety.

Knife selection should match user comfort.

Durability and Long-Term Use

Knife durability depends on:

-

Steel quality

-

Heat treatment

-

Maintenance

Proper care extends knife lifespan.

Regular maintenance preserves performance.

Conclusion

Kitchen knives such as the Matsato Knife reflect modern developments in blade design, material engineering, and ergonomic construction. Factors such as blade geometry, steel composition, hardness, balance, and handle design all influence knife performance.